Custom Flex LED Strip Industrial Design

High-Performance Custom Flex LED Strips for Professional Applications

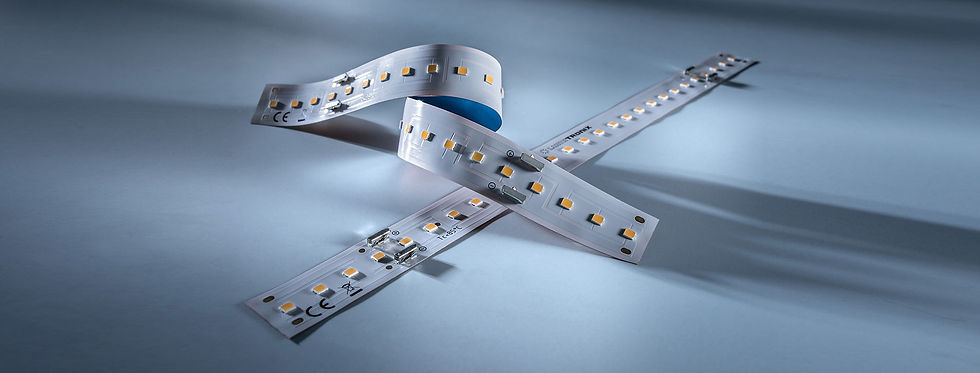

A Flex LED strip is a custom LED module built on a flexible printed circuit board (FPCB). Its ability to bend, curve, and adapt to tight spaces makes it an ideal solution for compact luminaires, long continuous lines of light, embedded lighting in machines or devices, and countless architectural or industrial applications. With lightweight construction and efficient component integration, Flex LED strips enable designs that are impossible with rigid PCBs.

Today, Reel-to-Reel (R2R) Flex manufacturing is transforming LED production in Europe. This advanced process allows continuous fabrication of flexible LED modules up to 100 meters long and 50 centimeters wide, delivering unmatched precision, consistency, and cost-efficiency. It enables high-volume production with superior quality—opening the door to the next generation of flexible lighting systems.

Flex LED strips also offer significant logistical advantages. A single 50-meter reel replaces over 100 individual rigid modules, reducing packaging, storage, handling, and installation time. For large or continuous lighting projects, Flex LED strips minimize wiring, simplify connections, and streamline implementation.

Design for Performance

With more than 20 years of LED design experience, we understand the full range of Flex LED strip applications—from architectural lighting and industrial machines to bioreactors, vehicles, and medical devices. Our industrial design process ensures that every custom Flex LED strip we develop is optimized for performance, reliability, and manufacturability.

During the design process, we evaluate all relevant performance criteria, define the exact specification values, and select the components that best meet them. This results in a highly optimized, manufacturable Flex LED Strip that delivers predictable, long-term performance.

Technical Characteristics We Consider

We evaluate all key technical parameters that define the performance and behavior of a custom Flex LED Strip—including optical output, electrical characteristics, spectrum, lifetime, thermal limits, form factor, circuit type, and protection factor—to ensure the design precisely matches the requirements of your application. Below a non-exhaustive list:

01

LED Luminous Flux

1 lm to 200 lm

03

White Color Temperature

10,000 h to 100,000+ h

05

White Spectrum Quality

CRI 70 to CRI 99

TM-30 metrics

07

Flex LED Strip Voltage

2 V to <270 V

09

Flex LED Strip Length

up to 100 meters (circuit repeatability max 600 mm)

11

Multicolor LED Module

Dual CCT, RGB, RGBW, RGB+W+WW, and more...

02

LED Lifetime

10,000 h to 100,000+ h

04

Color Wavelenght

260 nm to >800 nm (UV, VIS, IR)

06

LED Voltage & Current

1 V to 12 V

10 mA to 700 mA

08

LED Strip Circuit Type

Constant current

Constant voltage

10

Module Zhaga Standard

Zhaga Book 7

12

Waterproof rating

IP65, IP66, IP67, IP68

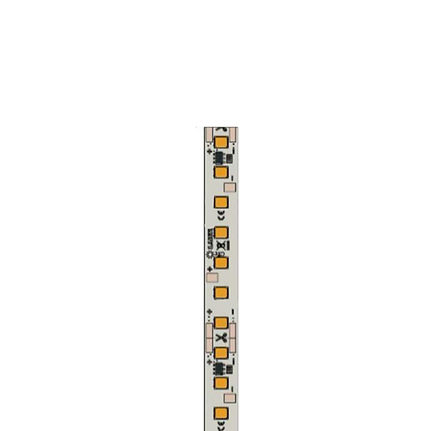

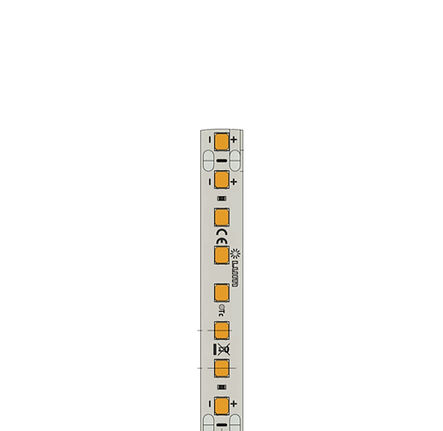

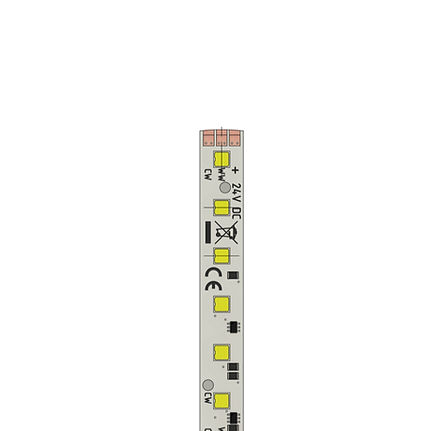

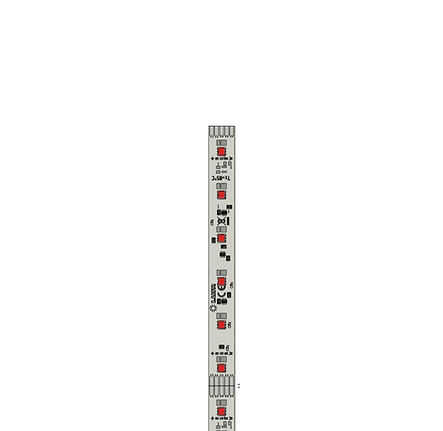

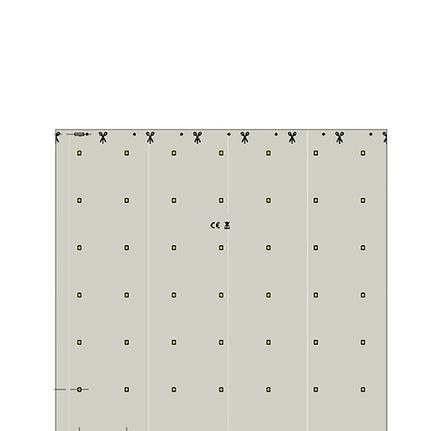

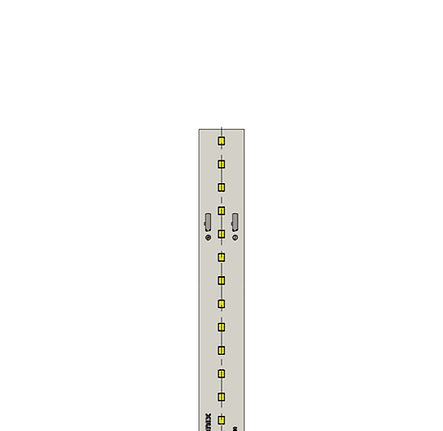

Sample Custom Flex LED Strip Designs

Starter Design Package

(Flex LED Strips)

Our Starter Design Package covers the major elements required to develop a professional, manufacturable Flex LED Strip. It provides a complete, technically mature foundation that many projects can directly build upon.

from 7,500 €*

Starter Package Includes

1 / Requirements Gathering & Specification Definition

We define all performance targets, project constraints, and industry-specific requirements to ensure the Flex LED strip is designed precisely for its intended application.

2 / LED & Component Selection

We select the optimal LEDs and components using advanced manufacturer tools, binning data, and early-access insights to ensure maximum performance and reliability.

3 / Design for Manufacturing (DFM)

We engineer the flexible PCB materials and layout for electrical, thermal, optical, and mechanical performance. Covers electronic design, mechanical integration, PCB layout, manufacturability optimization, product technical data and design file. 25 Hours of DFM are included in the starter design package.

4 / Design for Certification & Compliance

When required, we design Flex LED strips to meet relevant standards such as Zhaga, safety, EMC, and RoHS.

* Package Limitations

The Starter Design Package covers all major foundations for most Flex LED strip projects, but it does not guarantee final design completion. Additional work may be required depending on complexity.

Extensions can be purchased through:

• Additional Starter Design Package(s), or

• Extra Design for Manufacturing (DFM) hours at 300 € per hour

Terms & Conditions apply.

Deliverables

The design package delivers the Flex LED module technical drawing and specifications, optimized for manufacturing reliability. It provides a proven, production-ready foundation that enables you to advance smoothly to prototyping,

Ready to start your custom Flex LED Strip design?

Contact us today to discuss your project requirements.